SMT Basic Process:

SMT Line Logic:

Production is very important but quality comes first that's exactly why after each stage that add value in SMT we must apply inspection stage it's simply a desired waste to insure SMT line quality

What is AOI ?

The term AOI stands for Automatic optical inspection in which an inspection machine take pictures or measure height , volume and area (using laser beam) of SMT material and compare it to reference (image frame or value) and decide if it's defect or good product

SPI (Solder Paste Inspection):

An inspection machine that generate a 3D image of solder paste print using laser beam

to perform a 3D inspection by calculating and visualizing of Volume, height and area of solder paste on the PCB and view it in analytic way (Graphs, histograms and Pareto charts)

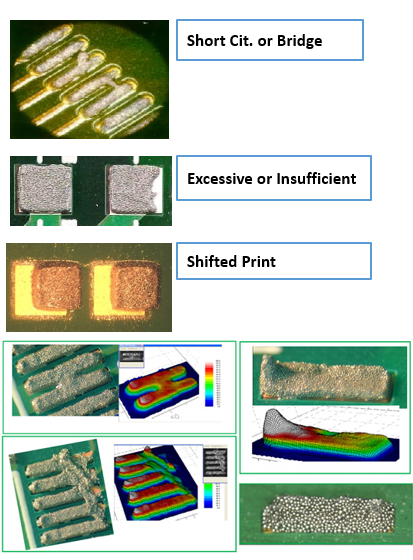

Defects:

Video: